FABRICATION/restoration

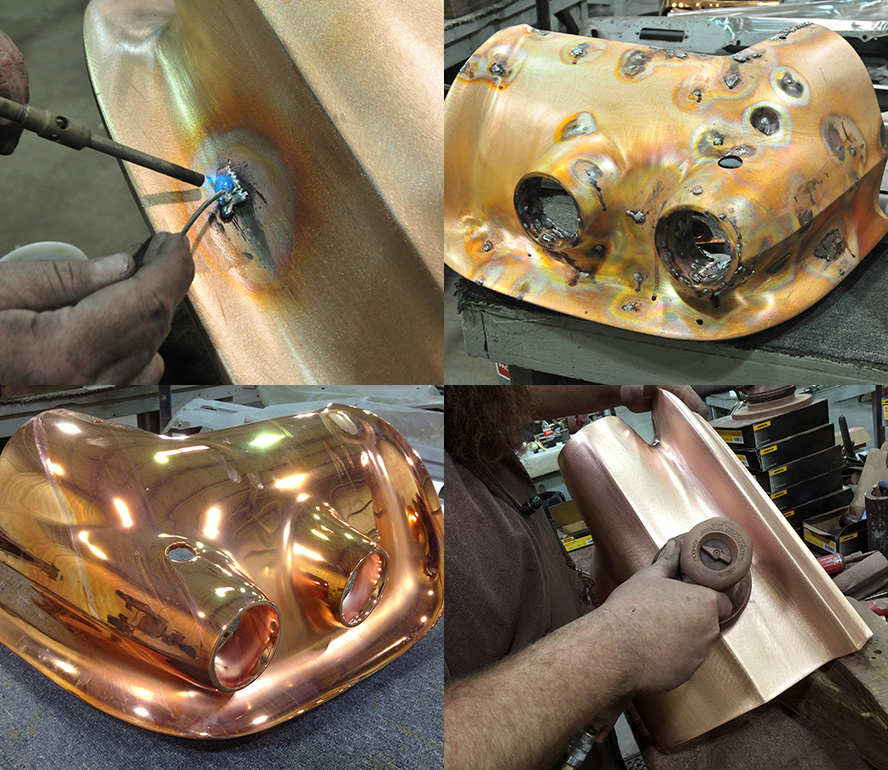

Due to different levels of deterioration, belting or sanding cannot be done if it jeopardizes the substrate itself and a different process is required. Restoring the surface will require an acid copper layer to be applied along with a re-sanding process. Remaining imperfections are then identified such as pits, scratches, or low areas. Low areas are then soldered and then “cut down” to match the copper surface and re-plated again in an acid copper bath. Upon inspection the piece either passes to plating department to finish the triple plate process or goes back into the copper and reworked, depending of the expectation of the finished piece.

Plating only enhances the quality of the surface that is to be plated. It is important that in this process that straightening, grinding, sanding, detailing, and buffing are done correctly to ensure a quality finish. It is the ability of our polishers and the pride they take in providing our platers with a beautiful surface to plate on.

-

Providing full range of high metal services solutionThere are many variations of passages of available but majority have alteration in some by inject humour or random words.

-

Get a solution for all industries in united kingdomThere are many variations of passages of available but majority have alteration in some by inject humour or random words.

-

Metal works crafts manship built to scaleThere are many variations of passages of available but majority have alteration in some by inject humour or random words.